ONS-01 Strategic Procurement & Industrial Capability

GSA SIN 311423 (Non-perishable foods) | National Security Food Manufacturing & Supply

1. Executive Summary:A Strategic Asset, Not a Supplement

ONS-01 is a mission-critical performance system engineered for U.S. military and allied force deployment.

It is engineered to solve the specific challenges of modern combat feeding: logistics friction, thermal degradation, and the physiological attrition of the Warfighter.

- Clinical vs. Commercial: Developed over 3 years by doctors, not marketers.

- Zero Footprint: 100% biodegradable/burnable; leaves no trace in theater.

- Total Stability: 24-month shelf life with zero refrigeration; storage-stable in extreme desert heat.

- Ready for GSA: Categorized under GSA SIN 311423 (Non-Perishable Foods). Regulatory documentation available upon request in accordance with applicable federal guidelines.

2. Procurement Strategy:Logistical Realities & GSA Pricing

Minimum Order Quantity (MOQ):

1 Metric TonTo maintain fixed GSA pricing and ensure total supply chain integrity, ONS-01 is supplied in 1-metric-ton increments. This ensures that forces receive thecumulative dosagerequired for clinical-grade physiological protection. The "Power of One Ton" (The 312-Soldier Metric)One metric ton is a specialized, high-density unit of readiness designed for unit-level deployment:

- Total Content: 28,090 individual 35.6g sachets.

- Daily Rations: 9,363 full 3-sachet daily protocols.

- Sustained Support: One metric ton supports 312 personnel for 30 days.

- Unit Cost (Delivered): $223,000 per Metric Ton.

- Daily Cost Per Soldier: $23.82 (Includes 3 sachets per day).

The Mission Logic

- Combat Readiness vs. Trial Orders: Small-scale, "trial-sized" orders (e.g., 5,000 sachets) are logistically inefficient and fail to provide the sustained physiological loading necessary for force-wide readiness.

- GSA Price Protection: Procurement in 1-metric-ton units aligns with GSA pricing structures and supports structured production scheduling within our high-capacity manufacturing facilities.

3. The Economics of Readiness:ROI vs. Injury Costs

The Military’s Most Expensive Problem: Musculoskeletal Injuries (MSKI)

While the daily cost of ONS-01 is fixed at GSA rates, the cost of inaction is volatile and extreme. Musculoskeletal injuries are the leading cause of medical evacuation, non-deployability, and early discharge across all U.S. Military branches.

The Financial Reality of the DoD:

- The Annual Burden: MSKIs cost the U.S. Department of Defense over $3.7 Billion annually in direct medical costs and lost productivity.

- The Individual Event: A single combat or training-related injury (tears, fractures, or chronic degradation) estimated to cost the DoD tens of thousands of dollars per incident in surgery, evacuation, and recovery.

- The Readiness Gap: "Limited Duty" days represent a hidden cost of over $4 Billion to the Army alone, as soldiers remain on payroll but cannot fulfill mission requirements.

The ONS-01 "Insurance" Factor:

By integrating ONS-01 as a mandatory daily readiness protocol, the DoD effectively "insures" its most valuable asset: the Warfighter.

- Break-Even Analysis: If the ONS-01 protocol prevents just one $50,000 medical event within a 312-soldier unit, the entire cost of the metric ton is effectively neutralized.

- Force Preservation: ONS-01 targets the specific root causes of non-combat attrition — connective tissue failure and central nervous system fatigue — where standard MREs and civilian proteins fail.

Conclusion

You are not procuring "powder"; you are procuring Personnel Availability and Long-term Budgetary Savings.

4. Global ProductionCapacity & Industrial Readiness

Current Operational Capacity

ONS-01 is currently in active, validated production.

Blackstone Group’s existing European manufacturing facility currently operates at:

260 metric tons per month of production capacity

This represents immediate readiness to support:

- National-level force deployment

- NATO-scale procurement volumes

- Multi-branch sustained operational programs

Production is active, validated, and scalable without dependency on new facility construction for initial contracts.

ONS-01 is deliverable at scale from day one.

Current monthly production capacity of 260 metric tons is operational and contract-allocatable for U.S. government requirements.

Operational Production Record

ONS-01 manufacturing processes have been operationally validated through multi-year production cycles under industrial-scale quality control systems. Full batch traceability, stability testing, and compliance documentation are maintained and available to authorized procurement officers upon request.

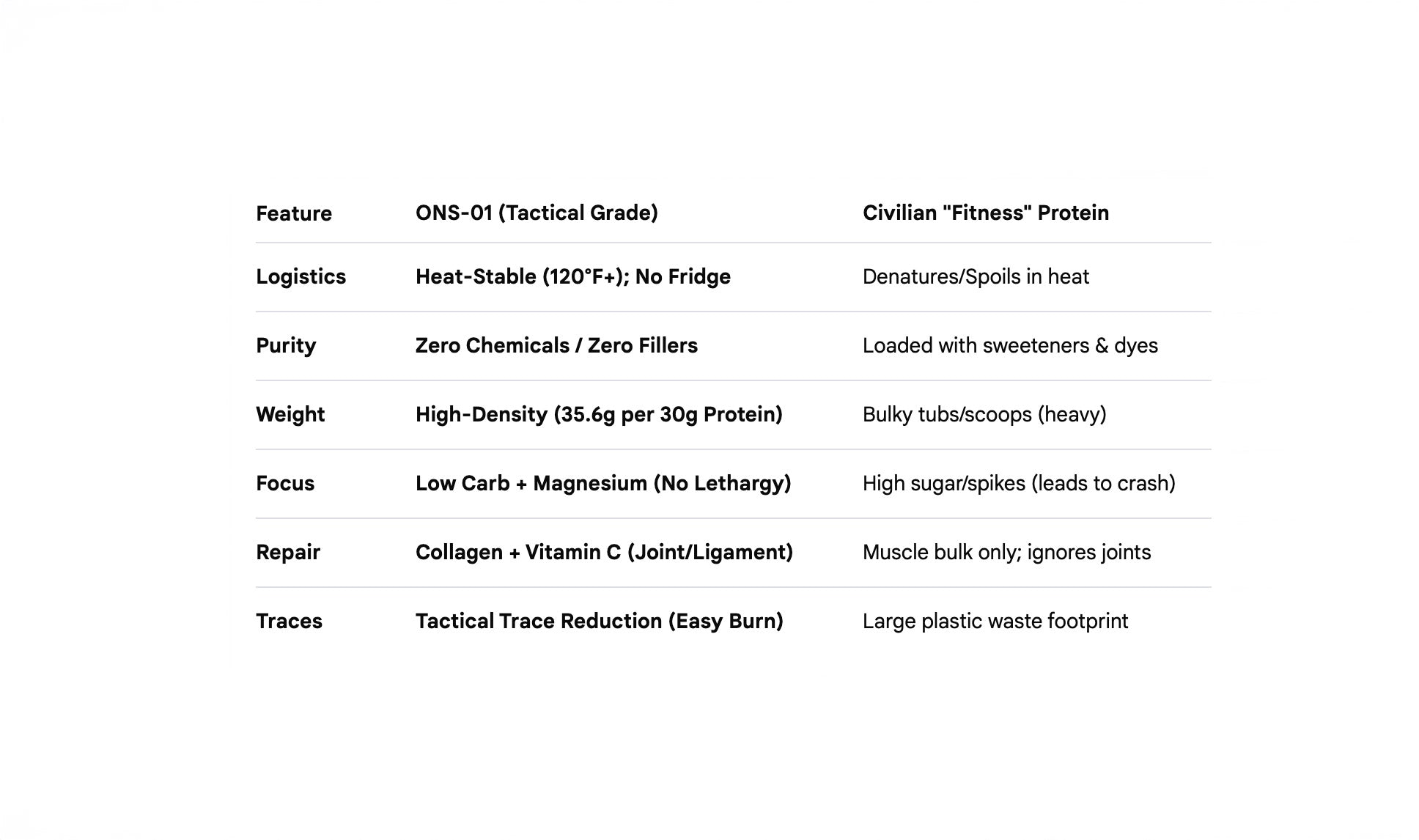

5. The "No Comparison" Metric:ONS-01 vs. Civilian Protein

6. U.S. IndustrialExpansion & Onshoring Strategy

Blackstone Group has formally communicated its commitment to strengthening the U.S. Defense Industrial Base through phased domestic manufacturing expansion aligned with long-term Department of Defense procurement agreements.

Structured Expansion Model

- Multi-site U.S.-based production facilities

- Designed for national and allied force-level demand

- Activation directly proportional to awarded contract scale

- Self-funded industrial infrastructure aligned with federal procurement stability

Expansion is structured to scale alongside multi-year defense contracts — not ahead of them.

This ensures:

- Controlled capital deployment

- Supply chain continuity

- Contract-aligned growth

- Zero speculative overbuild

7. Workforce & VeteranIntegration Commitment

Future U.S. facilities will prioritize the recruitment of U.S. military veterans across operational, supervisory, and technical roles.

This initiative is designed to:

- Integrate mission-aligned operational experience into production environments

- Strengthen cultural alignment with defense objectives

- Support long-term workforce stability within the defense manufacturing sector

Each U.S. facility is projected to generate:

1,500 – 2,000 high-skill American jobs

Workforce development will align with federal labor and defense industrial workforce initiatives.

Veteran workforce integration reduces onboarding friction for mission-specific production environments.

8. Sovereign Manufacturing Transition

Current production is located in France within a NATO-aligned industrial framework.

The long-term roadmap transitions production toward:

100% U.S.-based sovereign manufacturing

This transition is designed to ensure:

- Domestic supply chain security

- Elimination of cross-border logistics risk

- Strategic autonomy for U.S. defense programs

- Long-term production resilience

The transition timeline is contract-aligned and structured for continuity of supply.

Production is supported by multi-line manufacturing redundancy and raw material sourcing diversification to ensure uninterrupted supply under geopolitical disruption scenarios.

9. Surge Capability & StrategicReserve Alignment

Current production capacity supports high-volume, sustained deployment cycles.

The manufacturing structure is capable of:

- Rapid volume escalation under surge conditions

- Strategic reserve replenishment programs

- NATO-aligned multi-theater support

Capacity signaling is based on operational infrastructure, not projections.

10. ONS-01SF – Aerospace & MicrogravityAdaptation

ONS-01SF is a gel-based, ready-to-consume adaptation of the ONS-01 system engineered for environments where liquid mixing is impractical.

Designed for:

- Microgravity operations

- Aerospace deployment environments

- Extended-duration missions

ONS-01SF addresses accelerated musculoskeletal degradation observed in prolonged microgravity exposure.

Positioning remains capability-specific and independent from ground-force procurement structures.

11. Contractual & Contact Details

- GSA Schedule: MAS (SIN 311423)

- Contractor: Blackstone Group LLC-FZ

- Strategic Contact: Mario M. Radosavljevic, Executive Director

- Email: contact@blackstonegroupdubai.com

- Letters of Intent (LOI) regarding U.S. factory construction are available for review by authorized DoD/Congressional officials.